Foil Stamping

In printing on office supplies and advertising materials, the post-print appearance of products is just as important as the print itself. When promoting your brand, your customers will primarily examine the appearance of your material. You should never forget that flawless designs will help you stand out from your competitors. Therefore, we recommend you check out our foil stamping services. Additionally, we would like to note that our services include gold foil, silver foil, colored foil, and holographic foil options.

What is Foil Stamping?

When you ask, "What is foil stamping?", it can be defined as a process in which a shiny and metallic layer on a carrier film is easily transferred to other surfaces using both heat and pressure after the printing process. Foil stamping plays a significant role in luxury cardboard packaging production, offering an aesthetic appeal that cannot be achieved with methods like offset or screen printing.

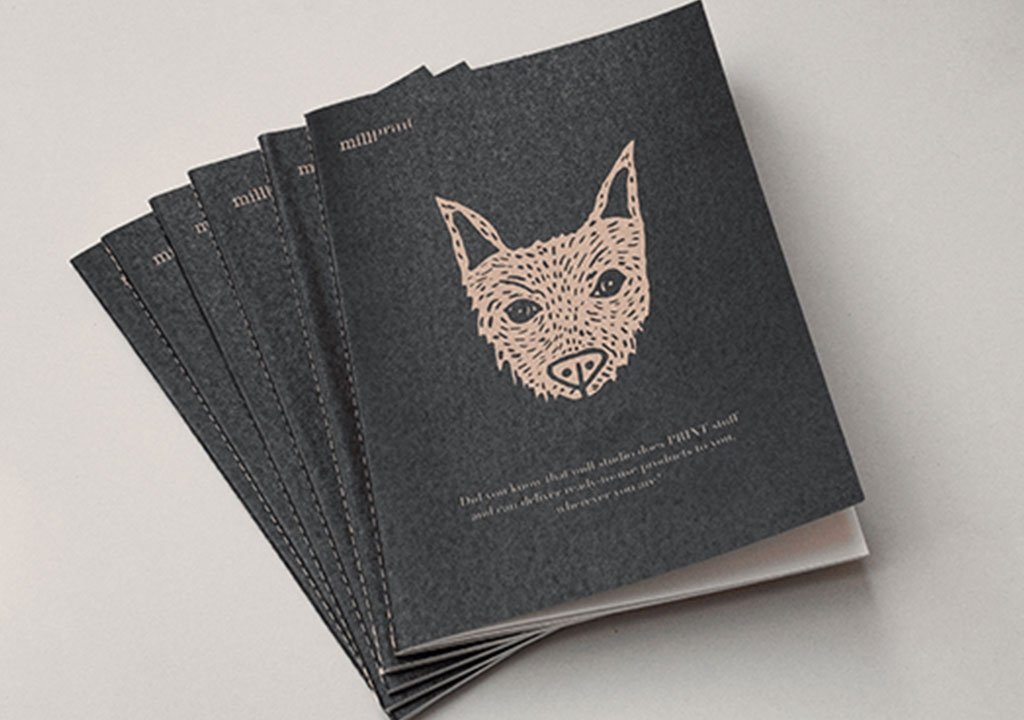

The foil stamping technique can be used to print text or decorations on hardcover books, as well as to bring vibrancy to materials such as fabric or leather. Additionally, it can serve as a security band for products like tickets, money, and labels. For foil stamping, the area to be applied must first be determined, and then a film output based on this area should be produced, as the foil stamping is done using molds based on the film output.

Foil Stamping Techniques

The primary foil stamping techniques are carried out in two methods: coating and die transfer.

Coating Method: In this method, after the material in coil form is printed, it is compressed with a hot press and a foil to transfer the design either partially or completely onto the material.

Die Transfer Method: In this method, the mold of the object to be printed is first installed on the machine. After heating the mold, the design on the mold is completely transferred to the material using foil. However, when we examine the printing process in more detail, it’s understood that foil stamping is a very skillful and meticulous job.

The master at the machine ensures that the printing is smooth and precisely aligned. The quality of the print entirely depends on the expertise of the operator. Unlike the offset printing technique, the metal or plates to be printed on must be heated to 120 degrees Celsius in the machine’s own chamber.

However, adjusting this process is quite difficult. Additionally, the ink and the lead-like inscriptions on the metal processed by the machine are transferred from the foil to the paper. After a series of challenging steps, a vibrant and shiny appearance is inevitably achieved. If the process is to be done without using foil, the absence of foil in the process is sufficient. In this case, the embossing technique used in printing can be applied, which is also known as debossing.

Foil Stamping Prices

Foil stamping prices vary based on the labor involved, the preferred printing method, and the materials used. However, we do not neglect to make payment processes easier for our clients after an order is placed. As the Seka Printing and Advertising team, we aim to maintain high-level service for all your printing needs.

We manage the printing process using high-tech machines and complete it with handcraft, delivering the product to your specified address within a minimum of 3 business days. If you want to add an aesthetic touch to your promotional materials and expand your target audience, don’t waste any time and get in touch with us! The Seka Printing and Advertising team is always here for your office supplies and advertising materials, as well as for any coating and embossing processes